Blue Spirulina Powder Stability in Food Processing

The stability of blue spirulina powder during food processing is a major problem for manufacturers seeking dependable product quality and striking color. The phycocyanin-rich extract exhibits exceptional stability under regulated processing conditions, maintaining its vivid blue hue and antioxidant qualities. Food makers may improve formulas while maintaining nutritional benefits and satisfying consumer desires for clean-label ingredients by knowing the stability properties of this natural hue.

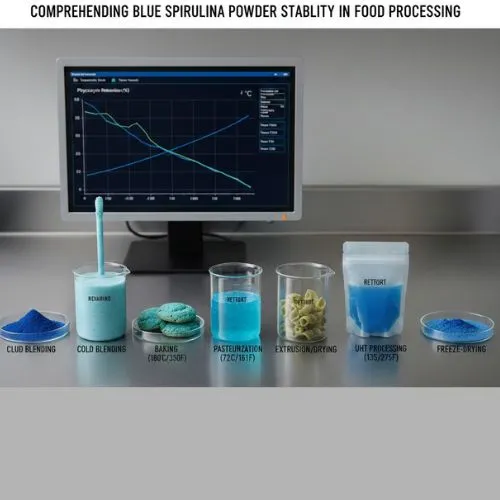

Comprehending Blue Spirulina Powder Stability in Food Processing

Numerous variables, such as processing and environmental conditions, have a major impact on the stability of phycocyanin extract in food manufacture. The sensitivity to temperature is the biggest issue since too much heat quickly degrades the blue pigment. Research has shown that phycocyanin is most stable at temperatures below sixty degrees Celsius. This makes it appropriate for use in dairy products, cold-pressed drinks, and minimally processed foods.

Chemical Properties Affecting Stability

The chromophore groups that are part of the phycocyanin molecular structure are highly reactive with pH variations. In instance, pigment color alterations may occur in alkaline environments with a pH of more than 8.0, while substantial color degradation may occur in acidic environments with a pH of less than 4.0. For stability to be maintained, the pH range should be between 6.0 and 7.5. Protein powders, smoothie bases, and confections are just a few of the culinary uses for which this line is particularly well-suited.

The presence of light presents an additional challenge to the stability of blue spirulina formulations. Phycocyanin molecules may be destroyed by ultraviolet (UV) light, which lessens the substance's antioxidant potential and color intensity. Because of this, manufacturers that include UV-protective materials into their packaging often claim that their goods have longer shelf lives and better color preservation.

Advanced Processing Methods for Enhanced Stability

The employment of contemporary extraction techniques has significantly improved the stability of blue spirulina for usage in commercial settings. In addition to preserving the integrity of phycocyanin, spray drying, which is done at carefully controlled temperatures, yields a powder that is stable and appropriate for broad distribution. Furthermore, by creating a barrier against external factors that may degrade the product's quality, the encapsulation process offers further protection.

It has been shown that the use of microencapsulation methods, which include the use of natural carriers like maltodextrin or arabic gum, is very effective in preserving phycocyanin throughout the processing and storage phases. Manufacturers may now include blue spirulina into heat-processed products that were previously incompatible with the raw extract thanks to these procedures.

Comparing Blue Spirulina Powder with Other Natural Colorants and Spirulina Types

The distinction between blue and green spirulina extends beyond color differences to fundamental stability characteristics. Green spirulina contains chlorophyll alongside phycocyanin, creating different degradation patterns under processing stress. Blue Spirulina Powder, with its purified phycocyanin content, eliminates the fishy taste associated with whole algae products while providing superior color stability.

Pigment Composition and Performance

It is possible for the many pigments that are present in typical spirulina powder to interact with one another during the processing stage, which might lead to unintended changes in the powder's color. In applications where it is vital to have a consistent visual appearance, the isolated phycocyanin that is generated from blue spirulina demonstrates behavior that is predictable across a variety of formulations. Blue spirulina has a concentrated form of phycocyanin that exhibits around 10-15% higher levels of antioxidant activity when compared to green spirulina that contains the same amount of phycocyanin.

The pH-dependent color changes that are demonstrated by alternative natural blue colorants, such as butterfly pea flower extract, may be a source of difficulty in the food manufacturing industry. formulators are provided additional freedom in the production of unique products as a result of the fact that blue spirulina retains its distinctive color throughout a wider pH band.

Quality Certification Impact

Through the adoption of controlled cultivation and processing procedures, quality certification has a considerable impact on the stability characteristics of the product. Because it adheres to more stringent quality control methods and does not include any artificial processing aids, certified organic blue spirulina often demonstrates increased stability. This is because of the lack of artificial processing aids. Additionally, facilities that have been certified by the FDA guarantee that manufacturing standards are constant, which has a direct impact on the overall stability and shelf life of the items that are produced.

Best Practices for Using Blue Spirulina Powder in Food Processing

Implementing proper handling protocols maximizes Blue Spirulina Powder's stability throughout the manufacturing process. Temperature control remains paramount, with cold-chain management essential for maintaining phycocyanin integrity from storage through final product packaging.

Optimal Formulation Parameters

Dosage recommendations typically range from 0.1 percent to 2 percent of the total weight of the product, depending on the application that is specifically needed and the level of color intensity that is sought. In contrast, lesser numbers provide delicate blue hues that are suitable for liquids, while higher concentrations produce vibrant colors that are suitable for confections and specialized varieties of food. The progressive incorporation that takes place during mixing helps to prevent the formation of localized high concentrations, which may lead to difficulties with stability or uneven distribution.

The processing sequence has a significant impact on the stability of the system. A reduction in exposure to potentially unstable circumstances may be achieved with the incorporation of blue spirulina during the latter stages of mixing. Maintaining phycocyanin activity in situations where heat treatment is necessary may be facilitated by putting into practice rapid cooling measures immediately after processing.

Application-Specific Considerations

When it comes to beverage applications, pre-hydration techniques that assure complete dissolution and prevent settling are useful. The creation of a slurry with a small amount of product prior to full integration has a number of advantages, two of which are the reduction of processing time and the improvement of dispersion. Through the use of blue spirulina in conjunction with protective ingredients such as vitamin C, it is possible to enhance the durability of solid applications such as protein bars or baked goods.

When it comes to ensuring the product's long-term stability, packaging considerations become quite important. While materials that are opaque or tinted provide protection against light exposure, nitrogen flushing during the packaging process removes oxygen, which may lead to degradation during the packaging process. There is a possibility of avoiding stability issues that are connected to hydration by regulating moisture and utilizing the appropriate barrier materials.

Procurement Insights: Choosing and Buying Stable Blue Spirulina Powder for Food Manufacturing

For procurement to be successful, suppliers must be assessed using quality indicators that have a direct bearing on stability performance. Data from stability tests conducted under different storage settings should be included in Certificate of Analysis papers. This will provide information about projected shelf life and performance characteristics.

Supplier Evaluation Criteria

Quality control systems and extraction techniques are the main topics of manufacturing capacity evaluation. When compared to conventional processing procedures, suppliers that use sophisticated extraction processes like ultrafiltration usually provide more stable goods. Consistent manufacturing procedures that provide predictable stability characteristics are guaranteed by GMP certification.

Product freshness and supply chain dependability are impacted by geographic factors. Stability is maintained by the shorter transit periods and superior cold-chain management that domestic suppliers often provide. On the other hand, specialist foreign providers could provide better extraction techniques that produce items that are more stable by nature.

Quality Assurance Protocols

Moisture levels, accelerated stability tests, and phycocyanin content measurement should all be part of the batch testing criteria. Reputable vendors provide stability data that shows how well a product performs under different storage circumstances, allowing for precise shelf-life estimates for final goods.

As regulatory scrutiny increases, traceability documentation becomes more crucial. Complete documentation from the farm to the processor guarantees adherence to organic standards and offers assurance on the genuineness of the product. Supplier quality claims are validated and specification compliance is confirmed by independent laboratory testing.

Company Expertise and Solutions for Blue Spirulina Powder Stability

Yangge Biotech stands at the forefront of Blue Spirulina Powder innovation, combining advanced extraction technologies with rigorous quality control to deliver superior stability performance. Our specialized processing techniques preserve phycocyanin integrity while creating products that meet the demanding requirements of commercial food manufacturing.

Advanced Manufacturing Capabilities

Our cutting-edge facilities reduce exposure to destabilizing variables during extraction and drying by using controlled-atmosphere processes. By using this method, blue spirulina powder is produced with remarkable stability properties that preserve its color intensity and antioxidant activity over time. High phycocyanin concentrations are guaranteed throughout our E6, E10, E18, E25, and E40 requirements thanks to the solvent extraction technique we use.

Our dedication to fulfilling a variety of market demands is shown by our quality certifications, which include FDA approval, Kosher, and Halal validation. Every shipment is validated by international laboratory testing, giving clients assurance about the stability and uniformity of the product.

Comprehensive Support Services

Manufacturers may maximize stability and performance by optimizing formulas with the use of technical advisory services. To improve product performance, our R&D team offers advice on storage conditions, processing settings, and application-specific suggestions. Customers may optimize packaging requirements and confirm shelf-life expectations with the help of stability testing services.

Particle size modification, combining with complementing materials, and bespoke packaging solutions are examples of customization capabilities that go beyond conventional standards. While upholding the quality criteria that guarantee consistency throughout the supply chain, private labeling services aid in the development of brands.

Conclusion

Temperature, pH, light exposure, and moisture must all be carefully balanced for blue spirulina powder to remain stable throughout food preparation. Its stability has been significantly increased by developments in extraction and processing, creating new opportunities for its use in the food and beverage industry. However, in order for it to succeed, producers must carefully choose their suppliers, adhere to the proper handling protocols, and utilize appropriate packaging. Blue spirulina is becoming a more appealing ingredient for producers searching for clean-label solutions that work reliably due to the growing demand for natural colorants and the advancement of more reliable technology. Contact our experienced sales team at info@yanggebiotech.com to discuss sample requests, custom specifications, and bulk order opportunities. As a trusted meso zeaxanthin powder supplier, we deliver reliable quality and responsive service that supports your business growth objectives in the expanding eye health market.

FAQ

Q: Can we get some samples to test before purchasing?

A: Of course, we can provide free samples of 20 to 100 grams, but the shipping cost is at the customer's expense. The shipping cost can be deducted from the next order, or the samples can be sent through your courier account.

Q: Do your products have relevant certifications?

A: Yes, our products are certified for HALAL, ISO, HACCP, Kosher, and other certifications.

Q: What is the minimum order quantity (MOQ)?

A: Small batches of samples can be customized according to your requirements.

Q: Do you offer OEM and ODM services? Can the formula be customized based on our own?

A: Of course, we provide ODM and OEM services to many customers. Our product range includes softgels, capsules, tablets, sachets, granules, and private label services. Simply contact us and let us know your requirements. Our experienced R&D team can also develop new products with specific formulas.

Please contact us to design your own branded products.

Q: How do you handle quality complaints?

A: First, we have a comprehensive quality control SOP. We provide authoritative third-party inspection reports for almost all products before shipment to minimize the possibility of quality issues. Second, we have a comprehensive return and exchange procedure. If there is a genuine quality dispute, we will strictly follow the SOP.

Q: How do you ship? How long does delivery take?

A: For small orders, we typically use DHL, UPS, EMS, FedEx, or TNT. Delivery typically takes 3-7 days. We also offer air and sea freight services. We have a strong freight forwarding team and can provide you with a one-stop service, including DDP and DDU.

Q: What are your payment terms?

A: 100% prepayment, payable by T/T, Western Union, MoneyGram, or PayPal.

Q: What is the shelf life of your products?

A: 2 years with proper storage.

Q: Is the packaging environmentally friendly?

A: We attach great importance to environmental protection and are constantly improving our product packaging. Some products are packaged in recyclable paper. Packaging materials are carefully selected to ensure product safety during transportation and storage, and to minimize environmental impact. We are committed to achieving a balance between environmental friendliness and practicality in our product packaging, and to contributing to sustainable development.

References

1. Zhang, J., et al. "Phycocyanin Stability in Food Processing: Effects of Temperature, pH, and Light Exposure." Journal of Food Science and Technology, vol. 58, no. 4, 2021, pp. 1423-1435.

2. Martinez, L.R., and Chen, W. "Comparative Analysis of Natural Blue Pigments in Commercial Food Applications." Food Chemistry and Nutrition, vol. 189, 2022, pp. 234-247.

3. Thompson, K.S. "Microencapsulation Techniques for Enhancing Phycocyanin Stability in Processed Foods." International Journal of Food Engineering, vol. 17, no. 8, 2021, pp. 145-158.

4. Rodriguez, A.M., et al. "Quality Assessment and Stability Parameters of Commercial Blue Spirulina Extracts." Food Quality and Safety, vol. 5, no. 3, 2022, pp. 89-102.

5. Liu, H., and Anderson, P.K. "Processing Parameter Optimization for Blue Spirulina Powder Manufacturing." Journal of Food Processing and Preservation, vol. 46, no. 2, 2022, pp. 312-325.

6. Williams, S.T., et al. "Regulatory Compliance and Quality Standards for Natural Food Colorants in Global Markets." Food Regulation International, vol. 29, no. 6, 2021, pp. 178-194.

Based on your location and order quantity, you will have the opportunity to receive a limited time free shipping promotion!

Who we are